Vacuum Pumps & Systems

Rotary Vane Vacuum Pumps Direct Drive

Vacuum Pumps & Systems

Rotary Vane Vacuum Pumps Belt Drive

About Us

We are highly capable in providing the clients with a widespread range of vacuum products, systems & related machinery, process equipment and instruments.

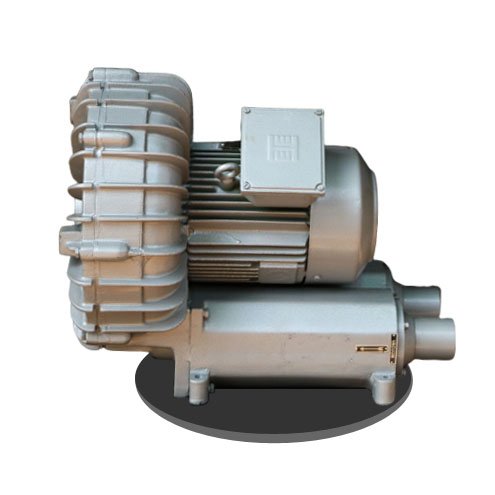

With an annual turnover of approximately 40 Million INR, today, our organization is counted amongst the reputed manufacturers, suppliers and exporters of a broad range of vacuum pumps and machinery like Water & Steam Jet Ejectors, Industrial Blowers, Turbine Blower, Lobe Vacuum / Pressure Blowers, Plants & Machinery, Industrial Pumps, Liquid Ring Vacuum Pump, High Vacuum Pumps,Diaphragm Vacuum Pump for various industries.

With the help of our advanced production unit and ultra-modern facilities, we provide product customization and modification as per the requirements detailed by the clients. Quality testing the products at par with highest Indian standards, we ensure that our efforts are inclined towards maximizing profits for the clients.

We are highly capable in providing the clients with a widespread range of vacuum products, systems & related machinery, process equipment and instruments.

Contact Us